Table of Contents

The business world has increasingly become driven by IT equipment, largely due to limited disadvantages. A firm heavily reliant on server infrastructure cannot cope with the daily operations when such breaks down or forces the market to rely on practically obsolete information circulation devices in a time where speed could mean everything. Other kinds of IT equipment, such as storage, network devices and more, are wholly critical to the functioning of the business world in the digital age . However, while many businesses invest a large amount of money in purchasing such equipment, this is not the end of considerations.

What is OEM Maintenance?

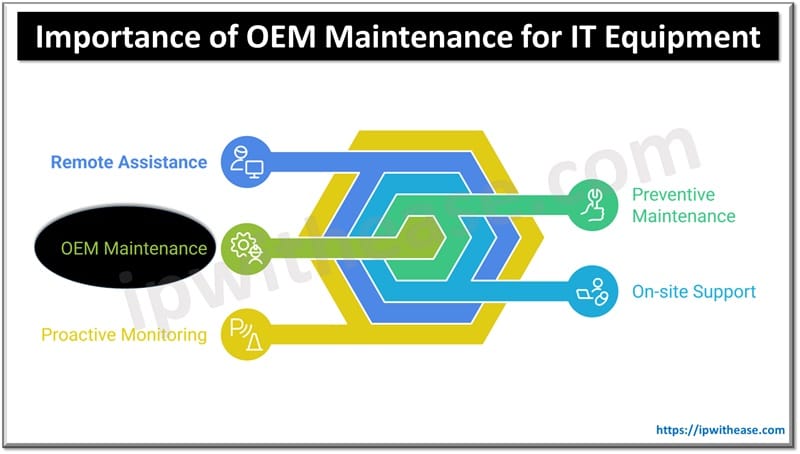

OEM maintenance ensures that the original equipment manufacturer of IT assets offers continuous support and service such as regular inspection, firmware upgrade, software update, trouble-shooting, and technical support. The purpose is to place IT equipment in the best state possible. Therefore, it facilitates the optimal function of the equipment, minimizes the downtime, and lastly, it extends the useful life of the equipment. The services under the OEM maintenance include preventive maintenance, which involves the regular checking of the equipment to make improvements where appropriate and avoid any area or item that might cause failure in the future and lead to downtime.

There is continuous on-site support, where necessary, to make sure the technician is just nearby and can offer his services in case of any physical location. Remote assistance allows firms to connect real time with the OEM technician who helps diagnose and repair their problem before it worsens. The last service is proactive monitoring, which allows the firm to monitor, diagnose, and fix the problem even before it leads to downtime.

Related: HIPAA Compliance & IT Infrastructure

Importance of OEM Maintenance for Optimal Performance and Longevity

To sum up, regular maintenance is vital in improving the functioning and service duration of IT equipment.

- First, since the equipment is maintained by the manufacturer, potential threats are discovered and rectified before they cause a system failure or downtime. The personnel are familiar with the product, and thus fixing the equipment is an easy and fast task, which makes system operation smooth.

- Secondly, the maintenance of equipment by the OE increases the proper functioning of the equipment, which leads to the capacity being served accordingly.

- Lastly, the maintenance serves to increase linearly the lifespan of IT equipment through reinforcing the structural support. Regular cleaning and checking enable the early detection of tear and wear signs.

Benefits of Using Genuine Parts and Components

The application of authentic OEM parts and components is crucial for efficient IT equipment servicing. Developing counterfeits or utilizing third-party parts do not guarantee the same standards of quality as original components. In practice, it causes compatibility issues and harms the equipment. Genuine parts, in their turn, are developed in such a way that it is impossible for the equipment to reject them. This way, OEM maintenance can guarantee that businesses apply gear with genuine parts, thus securing their investments from expensive repair and accelerated depreciation risks. Using non-OEM parts bears several risks.

The first and most evident is performance issues. Sometimes, the equipment can give not enough or even poor results, for others, unexpected failures. The second reason is the possibility of the withdrawal of manufacturer warranties. Genuine OEM parts always mean that the equipment complies with the manufacturer’s expected performance and maintenance requirements.

Related: What is Infrastructure as a Code (IaC)?

Access to Specialized Support and Expertise

Specialized support and expertise available is another major opportunity. Technicians that work for original equipment manufacturers receive extensive training and know the minor details of particular models and configurations of IT assets. This means that they can quickly and correctly spot issues, which helps a business receive support in as short a time as possible.

Apart from that, OEMs provide documentation, technical bulletins, best practices, and more, which a business can use to make sure its IT equipment has maximum performance and quickly address common problems. Due to the original provider, a business can get experience and technical ability accumulated during decades for the best results and stable IT performance.

Compliance with Warranty and Service Agreements

The maintenance of an OEM also requires adherence to warranty terms and conditions. OEMs provide warranty cover for their products, including the necessary support and repairs. Opting for third-party options of maintenance may cancel these warranties, leaving businesses exposed to potential costs and risks. Businesses need not spend additional cost on maintenance if they can utilize the expertise and resources of the manufacturer but OEMs require the organizations to comply with specific terms. While this condition is disadvantageous to an organization with no funds required for maintenance, it helps low-budget businesses achieve low-cost maintenance.

Additionally, OEM maintenance will support service agreements. Service agreements outline the services and the promptness with which the OEM will respond. Utilizing OEM services will help organizations meet what it has stipulated on the agreements and thus the required support and expertise.

Mitigation of Security Risks

Reducing security risks is crucial in the current digital environment. The threats to cybersecurity evolve every day, and IT equipment must be secured within the current letter against the new security vulnerabilities. Therefore, OEM maintenance is an important aspect of ensuring the security of IT equipment . OEMs develop and release up-to-date security patches at an early stage when security risks are out of sight. By always updating with this patch, the business is able to fight security threats in advance and stop potential security breaches. Furthermore, OEM technicians are always well-informed and update about the best security practices to employ.

OEM Maintenance Services

To benefit from the above-mentioned advantages, it is imperative to choose the most appropriate OEM maintenance service provider. To begin with, the provider’s reputation, experience, responsiveness, and international coverage is essential. In addition, businesses should focus on working with good OEM Maintenance service providers that sign appropriate service level agreements catering to their maintenance requirements and business needs. Furthermore, a business would actively benefit from providers specializing in on-site support, remote support, and proactive monitoring services.

Conclusion

In conclusion, without OEM maintenance, IT equipment cannot operate at peak levels of performance, reliability, and longevity. Using OEM maintenance ensures excellent equipment performance supported by real OEM components, special technical support, ensured warranty, minimal security, and legislation concerns. All of this and more may be provided by the right supplier of OEM maintenance. While these are significant advantages to OEM maintenance, they can be quickly negated if inadequate maintenance is obtained. Proper maintenance is likely to ensure the IT equipment’s longevity, and using the proper service provider assures it will run successfully.

ABOUT THE AUTHOR

IPwithease is aimed at sharing knowledge across varied domains like Network, Security, Virtualization, Software, Wireless, etc.